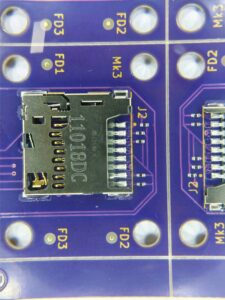

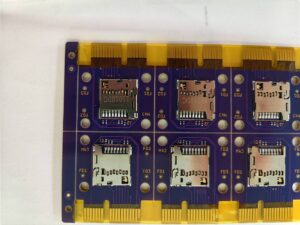

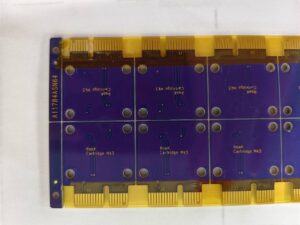

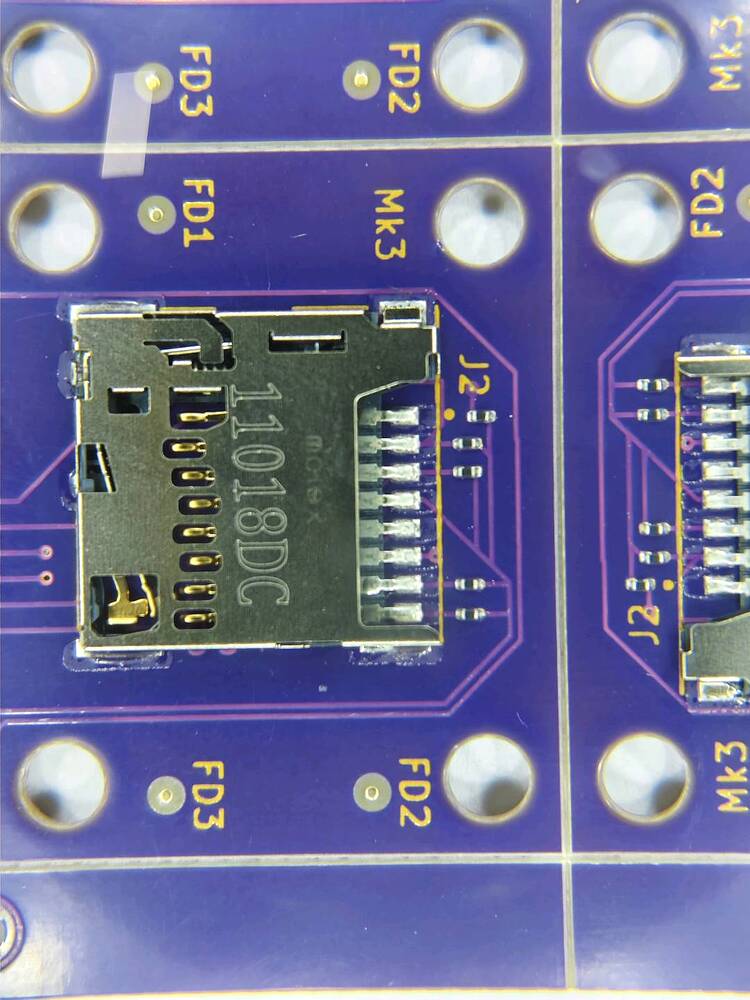

We just ordered 40 new cartridge PCBs—this time as panels. Here’s how the initial estimate looked:

On top of that, we even snagged a nice Thanksgiving discount! 🙂 I initially put in for 5 panels and configured each one with a 2×4 layout. That’s 8 PCBs per panel, making it 40 in total. During the panel design phase, the calculator flagged an error and asked for clarification. So, I confirmed again: I want 5 panels with 8 boards each. For the assembly (PCBA), I also specified 40 PCBs.

But then, the total came to $528 for 40 panels (which would be a insane 320 PCBs!!!). That would work out to $1.65 per PCB. If it really were just 40 PCBs total, we’d be looking at $13.20 per board—at that price, we’d definitely have to skip the gold plating! But looking at the other specs (board dimensions, lead time), it really seemed like they were calculating for 40 full panels.

So, I shot an email to my contact there (who had already reached out to say the order was under review anyway) to let them know something wasn’t right and to double-check the numbers.

Literally a few minutes later, I got a reply: I was right. They’ll adjust the price during the final calculation.

Alright, so now we have a solid price for the 40 cartridge boards. They swapped the “Hard Gold” finish for a “standard” one. I’m down to test it out and see how long it actually lasts. So far, I haven’t seen any real wear and tear on my current cartridges…

Still, we definitely need to stress-test how durable these are. If we decide we really want that Hard Gold coating, we’d probably need to order around 200 PCBs to keep the price reasonable. If a panel costs $80, we should be squeezing way more than 8 PCBs out of it. But since the minimum order is 5 panels… well, that’s going to be a lot of boards.

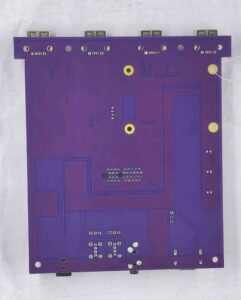

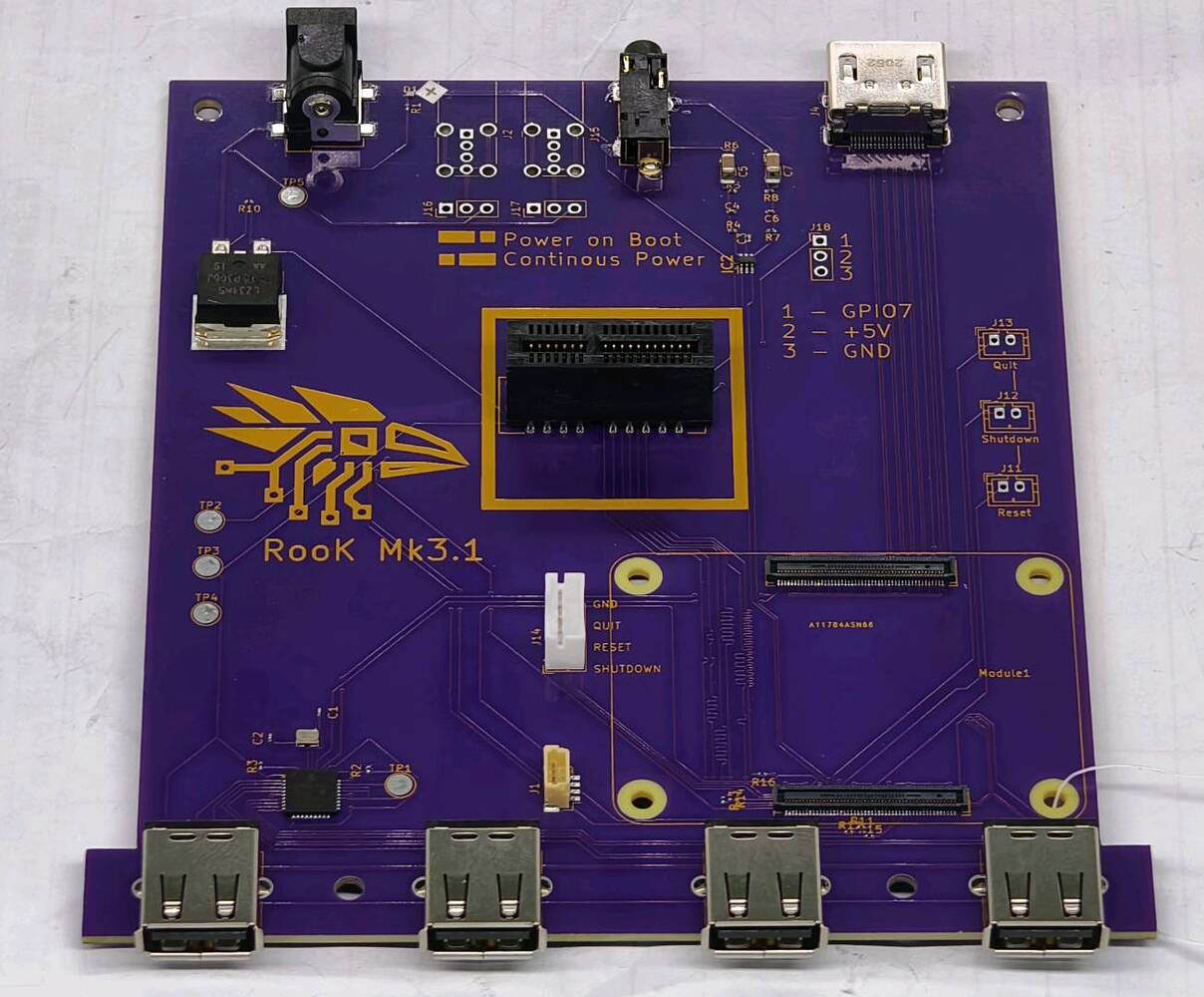

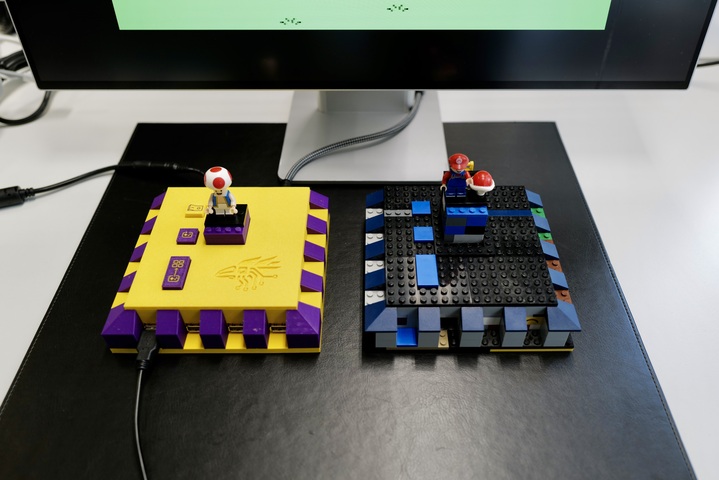

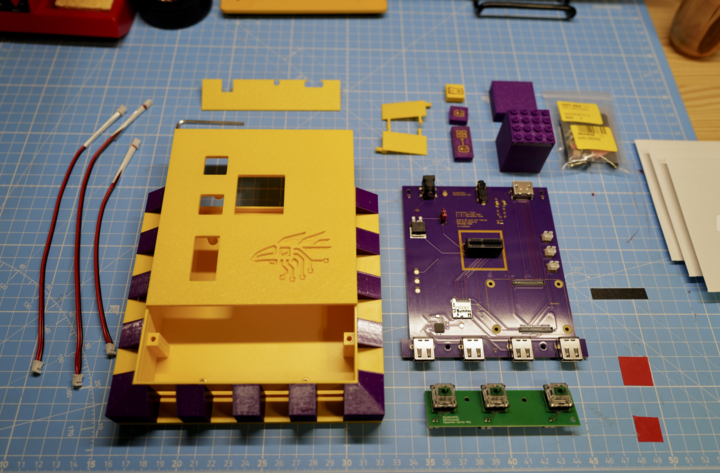

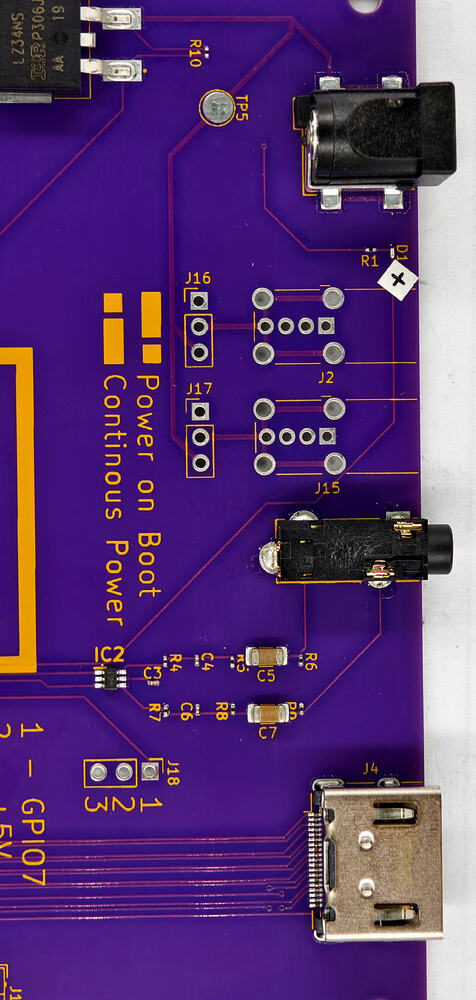

And finally: The cartridge PCBs arrived on Dec 23rd, and just in time for Christmas, the motherboards showed up on the 24th!

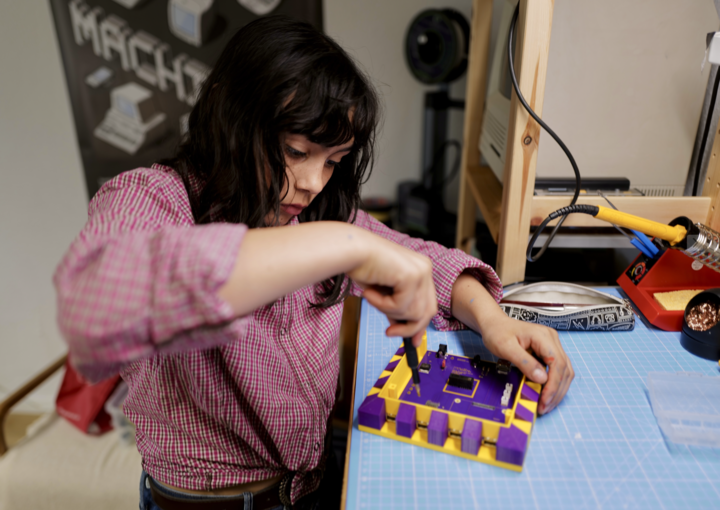

Enno tested one right away—and it works!

Now, the only thing left to do is rewrite the assembly guide.